Epoxy Coating

The Complete Guide to Epoxy Coating: Benefits, Types & Applications

Introduction to Epoxy Coating

Definition of epoxy coating

So, what exactly is epoxy coating? Think of it as a superhero for your floors and surfaces. This durable, versatile product is made from epoxy resin and hardeners, creating a chemical reaction that results in a strong, adhesive layer. Whether you’re looking to jazz up your garage with a shiny garage floor coating or protect industrial surfaces with chemical resistant epoxy, epoxy coatings have got you covered!

Brief history and evolution

The journey of epoxy coatings began in the 1930s when they were first developed as adhesives and sealants. Fast forward to the 1950s, and they started making waves in the flooring industry. Today, we have an impressive variety of options: from metallic epoxy floors that dazzle like a disco ball to DIY epoxy flooring kits that empower homeowners to unleash their inner artist.

With advancements in technology, we’ve seen innovations like UV resistant epoxy, waterproof epoxy coatings, and even eco-friendly epoxies. These developments not only enhance performance but also cater to our growing environmental consciousness.

Importance in various industries

The significance of epoxy coatings spans across numerous industries. Here’s why:

- Construction: Used for everything from basement floor coatings to high-traffic commercial spaces.

- Aerospace: Provides lightweight yet durable solutions with specialized formulations like high temperature epoxies.

- Agriculture: Protects surfaces with food safe epoxy coatings, ensuring safety standards are met.

- Marine: With options like marine grade epoxy coatings, these are essential for boats and docks.

- Aesthetic Applications: Decorative concrete coatings can transform dull surfaces into eye-catching designs.

The global epoxy coatings market was valued at USD 31.09 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 5.1% from 2021 to 2028. This growth reflects the increasing demand across various sectors for durable and effective surface solutions.

This versatility makes them indispensable for both residential and commercial applications!

If you’re considering an upgrade or new installation, understanding the ins and outs of epoxy coating is crucial. From selecting the right type for your needs to knowing how it can enhance your space’s functionality and aesthetics, this guide will be your go-to resource!

Your next step? Dive deeper into the benefits, types, and applications of this incredible material as we explore further in this guide!

Benefits of Epoxy Coating

Durability and Longevity

When it comes to flooring, durability is key. Epoxy coating is like that friend who never flakes out on you. Once cured, it forms a tough layer that can withstand heavy foot traffic, impacts, and even the occasional dropped tool. Unlike traditional flooring options, epoxy flooring can last for decades with minimal wear and tear.

Think of it as the superhero cape for your floors-strong enough to handle the daily grind while looking fabulous!

Chemical Resistance

If your space involves spills from cleaning agents or industrial chemicals, chemical resistant epoxy is your best bet. It acts like a shield against corrosive substances, making it ideal for garages, warehouses, and laboratories. No more worrying about unsightly stains or damage from harsh chemicals!

In fact, many businesses opt for industrial epoxy solutions specifically because they can handle the toughest environments without breaking a sweat.

Aesthetic Appeal and Customization Options

Let’s face it: aesthetics matter! With decorative concrete coatings, you can transform dull surfaces into stunning showcases. From vibrant colors to unique patterns with metallic epoxy floors, customization options are practically endless.

- High Gloss Finishes: Achieve that shiny look that reflects light beautifully.

- Colored Concrete Coatings: Want something bold? Go for bright hues!

- Textured Finishes: Add grip with an anti-slip epoxy coating.

Your floors can be as stylish as a runway model while still being functional!

Cost-Effectiveness Over Time

You might think that investing in epoxy floor paint is a splurge, but let’s break it down. The initial cost may be higher than traditional flooring options; however, the longevity and low maintenance needs make it a smart investment in the long run.

The average lifespan of an epoxy-coated floor is 10-20 years compared to 5-10 years for other types of flooring.

This means fewer replacements and repairs-saving you time and money in the long haul. Plus, who doesn’t love a good return on investment?

Ease of Maintenance

No one enjoys spending hours cleaning floors. With clear epoxy coatings, maintenance becomes a breeze! A simple sweep or mop will keep your surfaces looking fresh and clean.

- No Grout Lines: Say goodbye to dirt traps found in tile floors!

- Smooth Surface: Dust and spills wipe away effortlessly.

- Abrasion Resistant Coatings: Less wear means less hassle!

This ease of upkeep allows you to spend more time enjoying your space rather than scrubbing away grime.

The benefits of epoxy coating are hard to ignore! From its impressive durability to its aesthetic versatility, there’s no better choice for both residential and commercial spaces. So whether you’re considering a shiny new garage floor or upgrading your business’s industrial flooring, remember: investing in epoxy means investing in quality that lasts.

Your next step? Explore different types of epoxy coatings available on the market today to find the perfect match for your needs!

Types of Epoxy Coatings

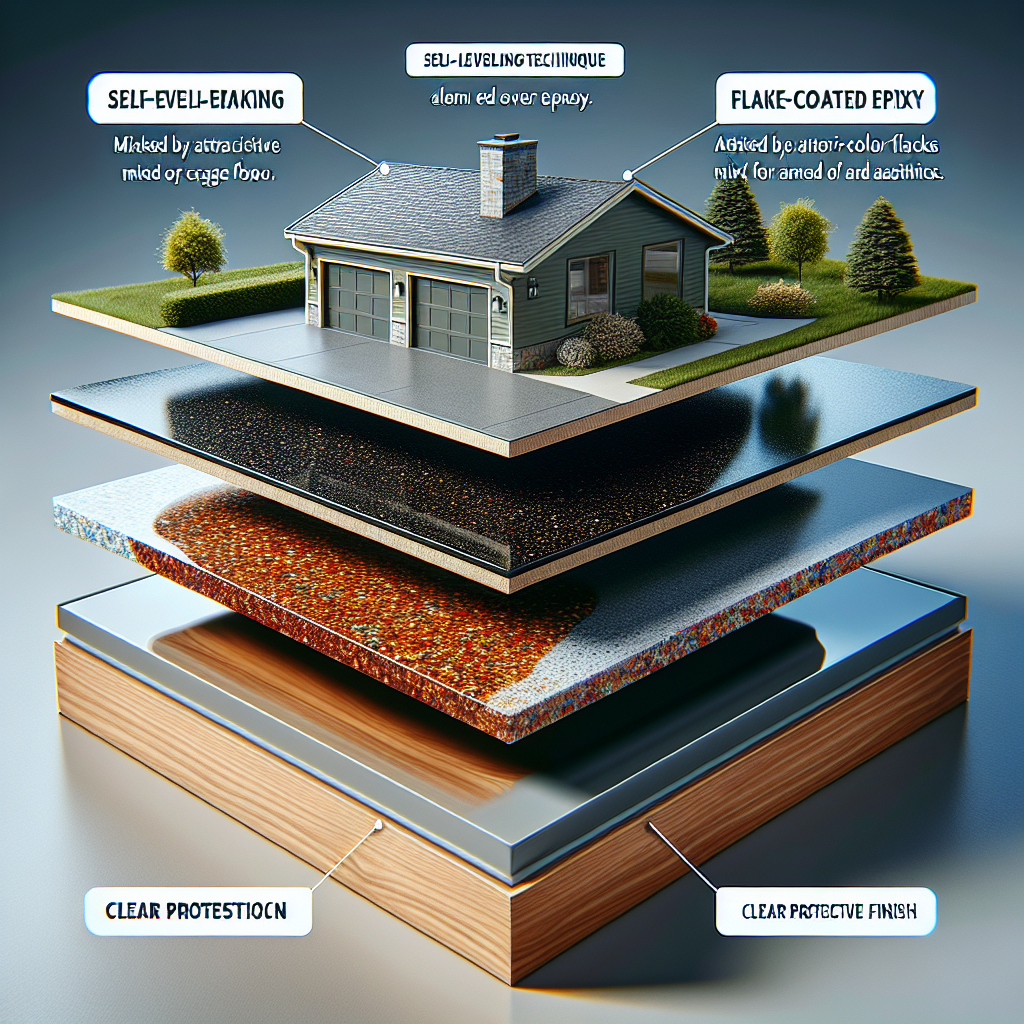

Self-leveling Epoxy Coatings

If you’re looking for a smooth, flawless finish, self-leveling epoxy coatings are your go-to solution. These magical mixtures flow and settle to create a seamless surface that’s as smooth as a baby’s bottom. Perfect for industrial epoxy applications or high-traffic areas, they provide both durability and aesthetic appeal.

Imagine a floor that not only looks great but also hides imperfections and irregularities! It’s like having your cake and eating it too-only this cake is made of tough resin.

Epoxy Mortar Coatings

For those who need something more robust, epoxy mortar coatings combine the strength of concrete with the adhesive power of epoxy. This type is ideal for environments that experience heavy loads or impacts-think warehouses or manufacturing plants.

These coatings are like the bodybuilders of the epoxy world; they can withstand serious wear and tear without breaking a sweat. Plus, they can be customized with aggregates for added texture and slip resistance!

Epoxy Flake Coatings

If you want to add some flair to your space while maintaining functionality, consider epoxy flake coatings. These colorful chips create a decorative finish that can brighten up any garage floor or commercial space.

- Aesthetic Variety: Choose colors and patterns that match your style!

- Durability: They offer excellent resistance against wear, chemicals, and stains.

- Anti-slip Surface: Great for safety in high-traffic areas.

Your floors will look like they just stepped out of a magazine shoot while staying tough enough to handle daily use!

Anti-static Epoxy Coatings

If you work in an environment where static electricity is an issue (hello, electronics manufacturers!), then anti-static epoxy coatings are essential. These specialized formulations help dissipate static charges, protecting sensitive equipment and ensuring safety.

This type of coating is like a superhero sidekick-always there to prevent surprises while you focus on getting the job done!

Clear Epoxy Coatings for Aesthetics and Protection

Clear epoxy coatings are perfect if you want to showcase your existing surfaces while providing an extra layer of protection. Whether it’s wood, concrete, or even decorative elements beneath the surface, these coatings enhance beauty while guarding against wear and tear.

- Aesthetic Enhancement: Bring out the natural beauty of wood grain or decorative concrete.

- Dirt Resistance: Keeps surfaces cleaner with less maintenance required.

- Mildew Protection: Ideal for areas prone to moisture exposure!

You get all the visual benefits without compromising on durability-now that’s what we call winning!

The versatility of epoxy coating types means there’s something for everyone-from DIY enthusiasts looking to tackle their own floors to businesses aiming for high-performance solutions. Don’t overlook the power these coatings bring to both aesthetics and functionality!

The world of epoxy coating is vast and varied! Whether you’re aiming for sleek self-leveling finishes or durable mortar options, understanding these different types will help you make informed decisions tailored to your specific needs.

Your next step? Explore which type fits your project best-your floors deserve it!

Applications of Epoxy Coatings

Residential Applications (Garages, Basements)

When it comes to residential spaces, epoxy coatings are the unsung heroes. Think about your garage: a place where tools, bikes, and maybe even that old sofa you swore you’d throw out live in harmony. With a durable garage floor coating, you can transform it from drab to fab! Plus, the high gloss finish not only looks stunning but also makes clean-up a breeze.

Basements? They can be damp and dreary. But with a quality basement floor coating, you can create a waterproof barrier that keeps moisture at bay while adding an aesthetic touch. It’s like giving your basement a makeover worthy of its own reality show!

Commercial Applications (Retail Spaces, Showrooms)

In the world of retail and commercial spaces, first impressions matter. Enter epoxy flooring. Imagine walking into a showroom with shiny, colorful floors that draw customers in like moths to a flame! Decorative concrete coatings can elevate any retail environment by providing both style and durability.

Moreover, these floors are resistant to staining and easy to maintain-perfect for bustling environments where spills are part of the daily grind. With options like anti-slip epoxy coatings, safety is also a priority!

Industrial Applications (Warehouses, Manufacturing Facilities)

For industrial settings, durability is non-negotiable. That’s where industrial epoxy shines! These heavy-duty floor coatings are designed to withstand heavy machinery and foot traffic without breaking a sweat. Think of them as the bodyguards for your warehouse floors.

Chemical resistant epoxy is particularly crucial here-protecting surfaces from spills that could otherwise cause serious damage. Whether you’re dealing with oils or other industrial substances, these coatings keep your floors looking pristine while ensuring safety.

Aerospace and Automotive Industries

The aerospace and automotive industries demand precision and performance-and so do their floors! Specialized formulations like high temperature epoxies ensure that surfaces remain intact even under extreme conditions. It’s like having superhero sidekicks for all those high-tech machines!

Clear epoxy coatings also play an essential role by protecting sensitive areas while showcasing intricate designs or branding elements on the floor.

Certain Specialized Environments (Laboratories, Hospitals)

Safety and cleanliness take center stage in laboratories and hospitals. Here, food safe epoxy coatings or even marine grade epoxy coatings provide surfaces that are not only durable but also easy to sanitize. Think of it as creating an impenetrable fortress against germs!

The bottom line? Using specialized epoxies helps maintain hygiene standards while ensuring safety in environments where every detail counts.

The versatility of epoxy coating applications means there’s something for everyone-from cozy homes to bustling commercial spaces and rigorous industrial settings.

No matter what type of space you’re working with, choosing the right application of epoxy coating can enhance functionality while adding an element of style. So whether you’re ready to coat your garage or revamp your retail space, remember: with epoxy, the possibilities are endless!

Your next step? Dive deeper into selecting the perfect type of epoxy coating tailored for your specific needs!

The Application Process of Epoxy Coating

Surface Preparation Steps

Before diving into the exciting world of epoxy coating, you need to prepare your surface like a chef prepping ingredients for a gourmet meal. Proper preparation is crucial for achieving that flawless finish. Here’s how to get started:

- Clean the Surface: Remove any dirt, oil, or grease using a concrete degreaser. Think of it as giving your surface a refreshing shower!

- Repair Cracks and Holes: Fill in any imperfections with a concrete patching compound. This step is like putting on your best face before going out.

- Etch the Surface: Use an etching solution or diamond grinder to create a rough texture. This helps the epoxy resin bond better, ensuring it sticks around for the long haul.

- Dry the Surface: Make sure everything is completely dry before applying epoxy. Moisture is like that uninvited guest at a party-it just ruins the fun!

Following these steps will set you up for success, ensuring your epoxy flooring adheres properly and lasts for years to come.

Mixing and Application Techniques

Now that your surface is prepped and ready, it’s time to mix up some magic! Here’s how to do it right:

- Select Your Epoxy: Choose between clear epoxy coatings, colored options, or even metallic varieties based on your desired look.

- Mixing Ratio: Follow the manufacturer’s instructions carefully-mixing epoxy resin and hardener in the wrong ratio can lead to disastrous results. Think of it as following a recipe; too much of one ingredient can spoil the dish!

- Pour and Spread: Once mixed, pour small sections at a time and use a roller or squeegee to spread evenly. This ensures no area gets neglected-like making sure every corner of your cake batter is mixed!

- Add Texture If Desired: If you want an anti-slip surface, sprinkle aggregate or sand while the epoxy is still wet.

This application technique not only enhances aesthetics but also adds functionality-perfect for high-traffic areas!

Curing Process and Timelines

The curing process is where all the magic happens! Here’s what you need to know about timelines and care during this crucial phase:

- Curing Time: Depending on the type of epoxy used (like fast setting epoxies) and environmental conditions, curing can take anywhere from 24 hours to several days.

- Avoid Foot Traffic: Resist walking on your newly coated floor until fully cured. Just because it looks beautiful doesn’t mean it’s ready for action yet!

- Avoid Heavy Loads: Keep heavy items off until completely cured-this prevents damage that could lead to costly repairs down the line.

- Mild Temperature Conditions Help: Ensure ambient temperatures are within recommended ranges (usually 60-85°F) for optimal curing results.

The final result? A stunning high gloss epoxy finish, durable enough to withstand whatever life throws its way-from spilled paint cans in garages to heavy machinery in industrial settings!

Taking care during each step of this process will ensure that your investment in epoxy coating, whether it be for home improvement or industrial use, pays off with lasting beauty and durability.

Your next step? Now that you know how to apply epoxy coatings like a pro, consider exploring different types available for specific applications tailored just for you!

Mistakes to Avoid When Using Epoxy Coating

Mismatched Product Types for Specific Applications

Choosing the wrong type of epoxy coating can be like wearing flip-flops to a snowstorm-totally inappropriate! Each application demands specific formulations, whether it’s marine grade epoxy coatings for boats or food safe epoxy coatings for kitchens. Always match your epoxy type with its intended use to avoid costly mistakes.

For example, using a standard epoxy floor paint in a high-traffic industrial area might lead to premature wear and tear. Instead, opt for heavy duty floor coatings designed to withstand the rigors of heavy machinery and foot traffic.

Ineffective Curing Methods or Conditions

Curing is where the magic happens, but if you cut corners here, you might end up with a floor that’s more “meh” than magnificent. Proper curing is essential for achieving that durable finish we all crave. Skipping this step or rushing it can lead to issues like bubbling or peeling.

- Follow Manufacturer Guidelines: Always adhere to the recommended curing times and conditions.

- Avoid Moisture: Humidity can wreak havoc on your curing process-think of it as inviting uninvited guests to your party!

- Temperature Control: Ensure temperatures are within the optimal range (usually 60-85°F) during curing.

A little patience goes a long way in ensuring your epoxy flooring looks stunning and lasts longer!

Lack of Proper Ventilation During Application

If you think applying epoxy coating is just about mixing and pouring, think again! Proper ventilation is crucial during application. Without it, you risk inhaling harmful fumes from the resin and hardener mixture.

- Open Windows: Let fresh air circulate while working-your lungs will thank you!

- Use Fans: Position fans strategically to help disperse fumes in enclosed spaces.

- PPE Matters: Wear masks and gloves; safety first!

A little foresight can keep both you and your project healthy!

Navigating Temperature and Humidity Challenges

The weather can be your best friend or worst enemy when it comes to applying epoxy coating. High humidity levels can delay curing times, while extreme temperatures can affect how well the epoxy adheres. Here’s how to navigate these challenges:

- Avoid Extreme Conditions: Try not to apply epoxy in extreme heat or cold; aim for mild temperatures instead.

- Check Humidity Levels: Use a hygrometer to monitor humidity; aim for levels below 70% for optimal results.

- Tweak Your Schedule: If conditions aren’t ideal, consider postponing your project until Mother Nature cooperates!

Your patience will pay off with a flawless finish that stands the test of time!

Avoiding these common mistakes ensures that your investment in epoxy coating, whether for residential or commercial use, yields beautiful results that last for years. Remember: preparation is key!

The next step? Armed with this knowledge, dive into selecting the right type of epoxy coating tailored specifically for your needs!

Conclusion: The Future of Epoxy Coating Technology

As we look ahead, the world of epoxy coating is evolving at a rapid pace. With innovation at the forefront, here are some key trends shaping the future:

- Emerging trends in epoxy formulations: New formulations are being developed to enhance performance and expand application possibilities. Expect to see innovations that offer improved adhesion, faster curing times, and even more customizable options.

- Sustainability considerations in epoxy production: Eco-friendly epoxies are gaining traction as manufacturers respond to environmental concerns. These solvent-free epoxies and low odor epoxies not only minimize harmful emissions but also cater to health-conscious consumers.

- Innovative uses in new industries or applications: Epoxy coatings are making waves beyond traditional applications. From food-safe coatings in kitchens to advanced solutions for aerospace components, the versatility of epoxy is being harnessed across diverse sectors.

The future looks bright for epoxy coating, with ongoing research and development paving the way for smarter, more sustainable solutions that meet modern demands.

The takeaway? Stay informed about these trends as they could impact your choices in flooring and surface solutions. Whether you’re a DIY enthusiast or a business owner, embracing these advancements can lead to better outcomes for your projects!

Your next step? Keep an eye on emerging technologies in the epoxy space and consider how they can elevate your projects-because who doesn’t want their floors to be not just functional but also cutting-edge?